Remote monitoring

Keestrack-er analytics software

With large fleets and multiple sites in operation it is essential that owners know the location and status of their machines in real time, 24 hours a day.

In response, we have developed the Keestrack-er telematics software system that provides real-time data and analytics via a web portal. The system enables you to check the location of machines and if they are working correctly. All aspects of a machine can be checked and if necessary, remote updates to the software can be made. It is possible to run diagnostic tests for all components include the feeder, screen, crusher, engine and conveyors. The Keestrack-er also adds an extra dimension to maintenance planning, helping to keep machines in operation for longer.

Advantages

-

Control

The Keestrack-er allows you total control of your machines from anywhere in the world.

-

Monitor

Know where your machines are and what they are doing 24 hours a day 7 days a week.

-

Test

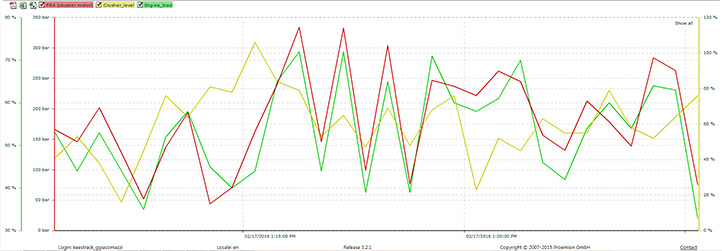

Remotely check machine parameters, run tests and receive real time reports.

-

Service

Remotely update all software, accurately plan maintenance and reduce your service time.

GPS and Geo-fencing

With the GPS function you can locate a machine 24/7 and tracked its route, distance and speed.

Setting up a Geo-fence is also possible with the system. Geo-fencing means setting up a designated area in which the machine can function. If a machine strays from this area, it will automatically shut down.

Reporting

With Keestrack-er you are able to store and retrieve data and create reports to track the operations of your machines over time. This is powerful data that can be used to drive efficiencies, plan for spare and wear parts and ongoing maintenance.

- Remotely check machine parameters and run tests

- Remotely update software

- Maintenance can be planned more accurately

- Possible to connect additional parameters

The technology

The system uses a GSM/UMTS (Universal Mobile Telecommunications System) modem system combined with a GSM/GPS antenna with a CAN-BUS network to communicate between the modem and the controller.

Using the CAN-BUS (Controller Area Network) is advantageous because it requires less cabling and is therefore easier to integrate into the structure of the machine. This means more sensors can be used which improves the quality and integrity of the data gathered.